Top Advantages of Wesense Solutions for Semiconductor Manufacturing

Consistent Performance

Our products maintain exceptional linearity, which is crucial for preserving product quality and operational consistency in semiconductor manufacturing.

Rapid Response

Engineered for efficiency, our compact and lightweight motion solutions optimize space. Designed for ultra-fast response times, Wesense systems provide quick and precise adjustments, keeping pace with the rapid demands of semiconductor processes.

Nanometer-Grade Accuracy

Wesense encoders and motors deliver the high resolution and accuracy required for semiconductor applications, ensuring meticulous control and measurement down to nanometers.

Reliable in Specialized Environments

Wesense encoders and motors are vacuum-compatible, ensuring reliable operation in environments with vacuum conditions and maintaining performance in specialized semiconductor settings.

Comprehensive Solutions Tailored for the Semiconductor Industry’s Precision and Efficiency Needs

In the high-precision world of semiconductor manufacturing, every micron—and often every nanometer—matters. The performance of your motion control systems can determine the success or failure of an entire process. At Wesense, we provide cutting-edge encoders, motors, and drives tailored to the unique challenges of the semiconductor industry.

Here’s how our technology supports precision, speed, and reliability at every stage of semiconductor production:

Unmatched Resolution for Nanometer-Scale Demands

Go Beyond Microns

Semiconductor applications often require resolution down to nanometers. From wafer inspection to lithography, precision is non-negotiable.

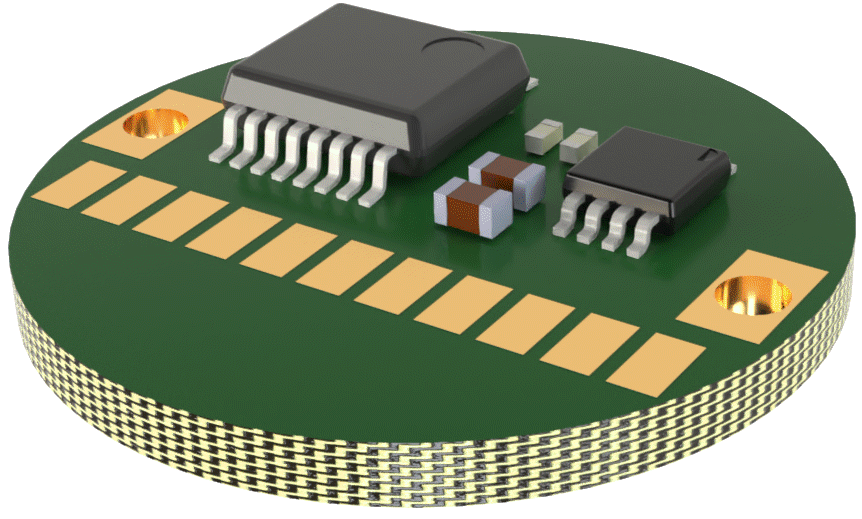

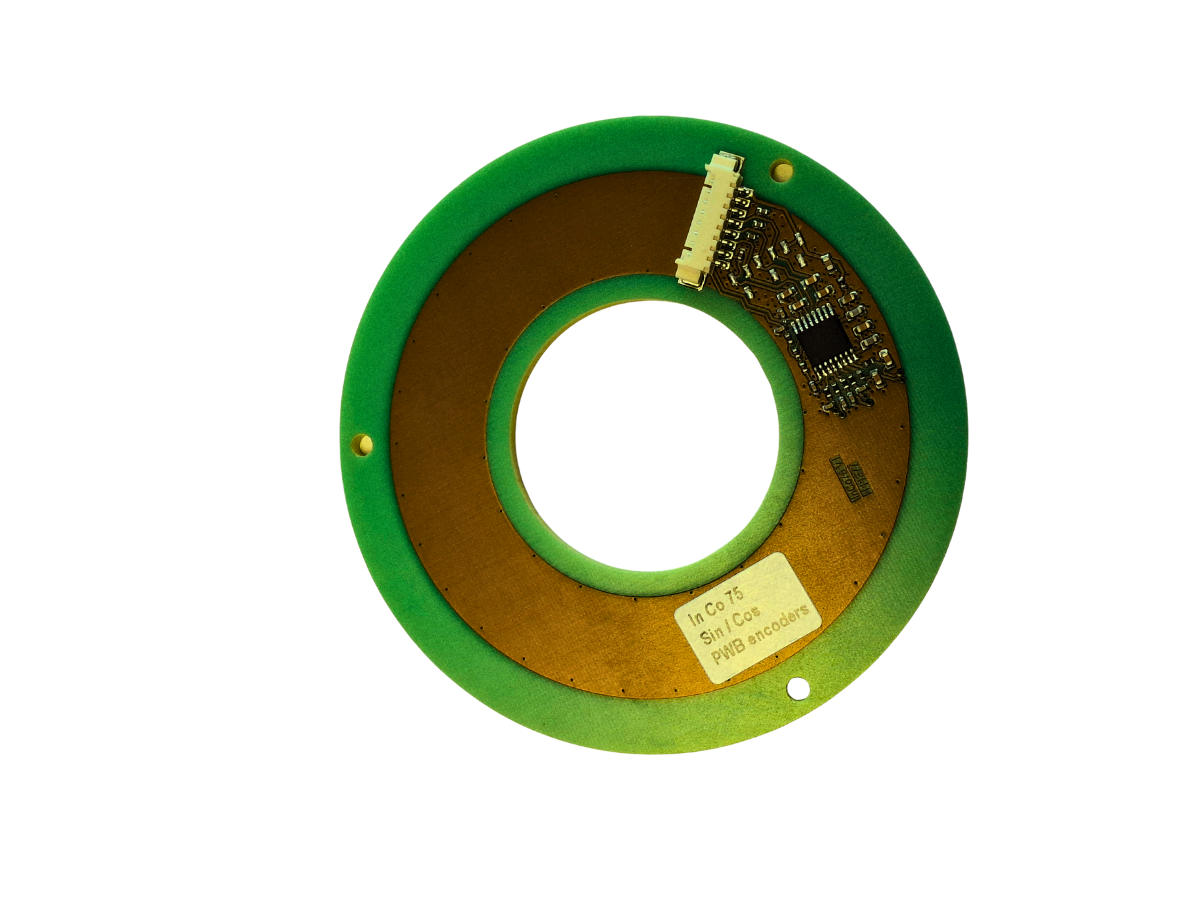

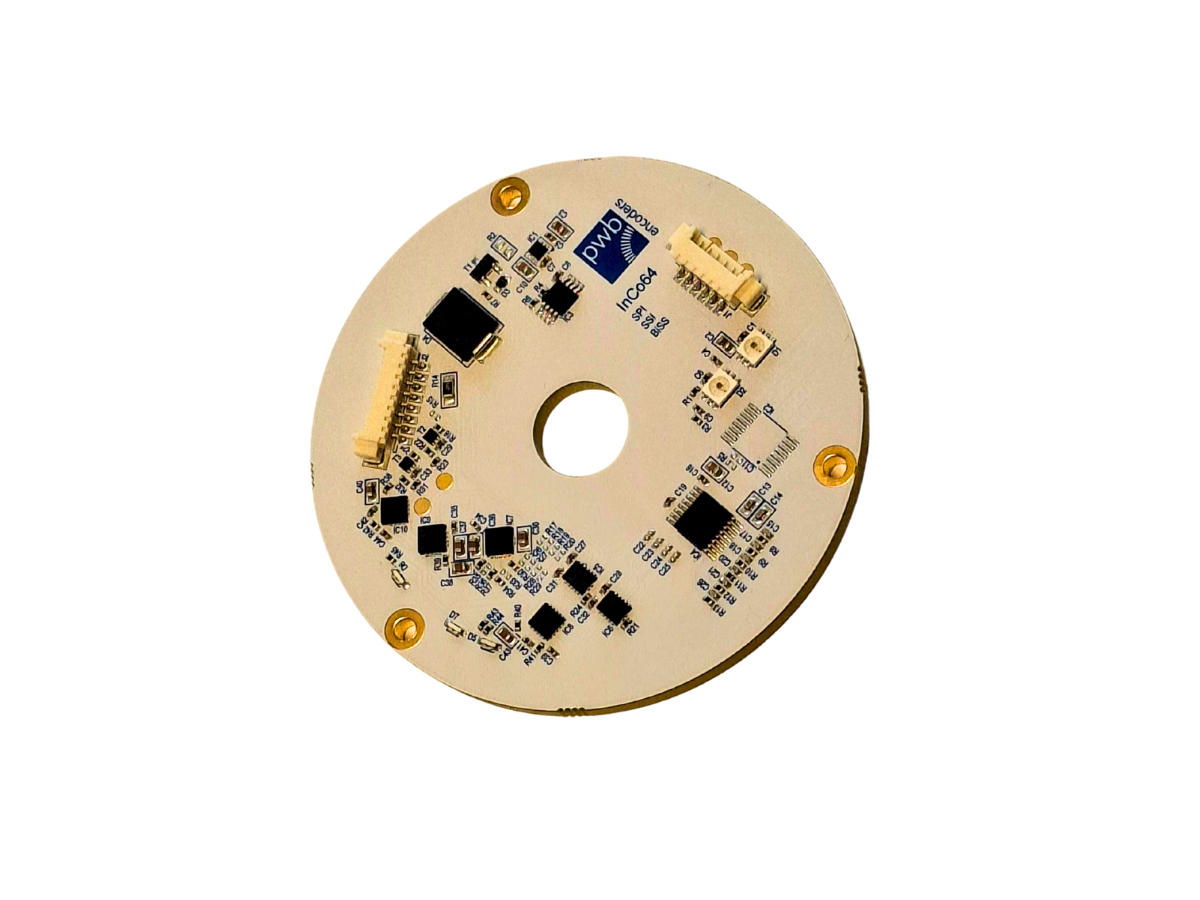

Encoders Built for Extreme Precision

Wesense encoders deliver exceptionally high resolution—ensuring each movement is measured with extreme accuracy. This level of precision supports demanding applications like stage control, pick-and-place systems, and high-resolution imaging.

High-Resolution Motor Control

Our motors complement encoder performance with fine-tuned motion control, allowing for gradual adjustments with smooth, accurate operation. This is essential for slow, delicate movements found in process equipment and test systems.

Superior Accuracy for Consistent Yield

Reduce Errors, Increase Throughput

Accuracy isn’t just about getting the position right—it’s about doing it consistently. Wesense systems minimize deviation to ensure reliable production cycles.

Closed-Loop Feedback Systems

Combining our encoders and drives in a closed-loop configuration ensures real-time corrections, boosting system accuracy and reducing cumulative errors.

Ideal for Critical Stages

In mask alignment, wafer bonding, and metrology, absolute accuracy determines success. Our components are tuned for these ultra-sensitive environments.

Engineered Linearity for Predictable Motion

Why Linearity Matters

Linearity ensures that movement follows a consistent path. Even the slightest non-linearity can lead to defects in semiconductor components.

Precision Engineering

Wesense encoders are calibrated for excellent linearity across the full range of motion—helping maintain the exact positioning required in applications like die bonding and etching.

System-Level Optimization

Our solutions are designed not just as individual components, but as part of a larger system that requires harmonized motion control.

Ultra-Fast Response Time for High-Speed Processes

Microseconds Make a Difference

Semiconductor production operates at high speed. Whether it’s handling wafers or inspecting dies, fast response times are essential.

Low Latency Systems

Wesense encoders and drives are optimized for microsecond to nanosecond response times, enabling real-time adjustments during high-speed operations.

Enhanced Control and Feedback

Quick feedback loops allow for more accurate positioning, better process synchronization, and minimized delays.

Flexible Signal Output Options

Absolute or Analog? You Decide

Different applications require different signal types. That’s why we offer both absolute and analog output options.

Integration with Existing Systems

Our wide signal compatibility ensures seamless integration into existing control architectures—whether legacy or modern.

Application-Specific Solutions

From cleanroom robotics to vacuum chambers, our team can recommend the best signal configuration for your environment.

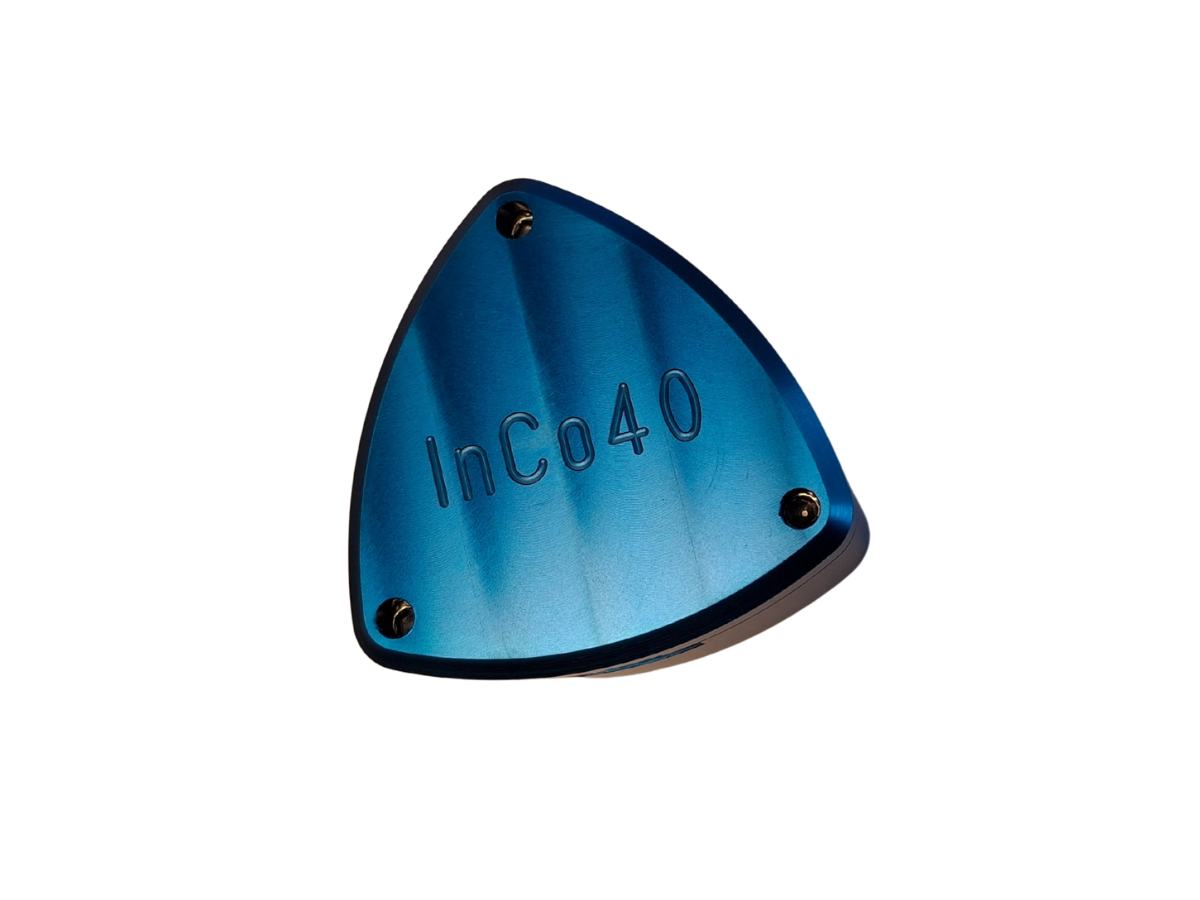

Reliable Operation in Harsh Environments

Built for the Cleanroom—and Beyond

Semiconductor manufacturing environments can include high humidity, wide temperature ranges, vibration, and even corrosive conditions.

Rugged Design

Wesense encoders and motors are built to endure these challenges. Our components maintain performance under vibration, contamination, and thermal variation.

Long-Term Reliability

Reduced maintenance and failure rates mean fewer interruptions in production and higher long-term ROI.

Vacuum-Compatible for Specialized Equipment

Designed for Low-Pressure Environments

Many semiconductor processes occur in vacuum conditions—especially in deposition, ion implantation, and etching.

Outgassing and Contamination Control

Wesense components are built using vacuum-rated materials that prevent outgassing and resist contamination.

Precision Without Compromise

Even in vacuum, you can expect consistent, high-resolution performance.

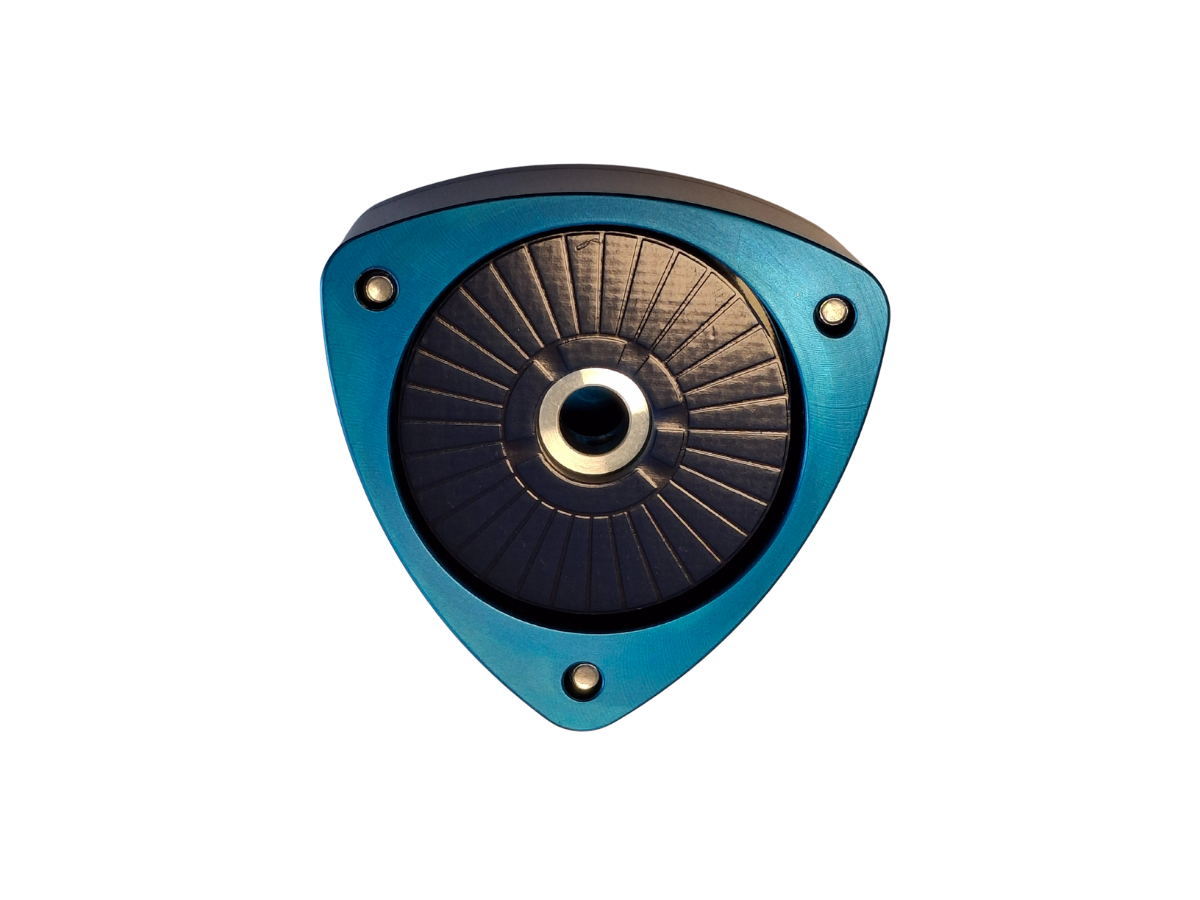

Compact Form Factors and Flexible Mounting

When Space Is Limited

Semiconductor tools often have limited space for motion components. That’s why we offer compact, low-profile solutions.

Easy Integration

Multiple mounting configurations and form factors allow for seamless integration into existing machines and new designs alike.

Efficiency Without Sacrificing Power

Our compact components don’t compromise on power, precision, or durability—making them ideal for miniaturized or modular systems.

The Wesense Advantage

By addressing every critical motion control parameter—from resolution to response time, and from ruggedness to vacuum compatibility—Wesense empowers semiconductor manufacturers to achieve the precision, consistency, and speed required in today’s competitive market.

Let Wesense help you push the limits of what’s possible in semiconductor production.